Now @orulz, from your observations with GoTriangle’s proposed 8-2-8-2 schedule, what kind of dwell times do you see on either end of the line?

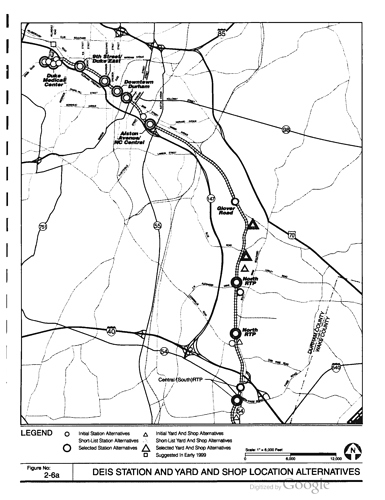

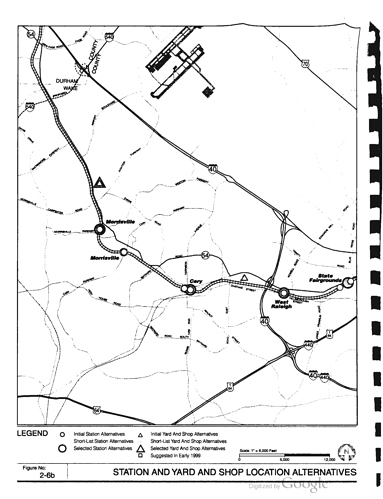

Or, for that matter, where would you put the storage and maintenance yard?

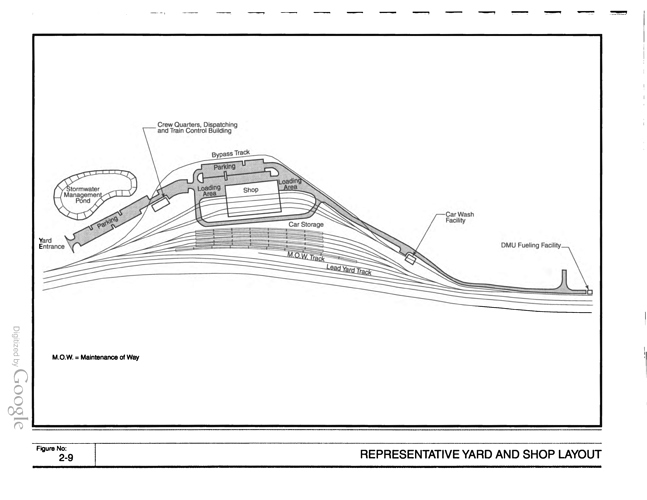

This was the representative schematic for the maintenance operation in TTA’s Regional Rail proposal…

I had to go back and look up the options (notated by the triangle) suggested by TTA in the 1990’s…